Emergency Information

In the case of an emergency, please call Washington University School of Medicine Campus Safety at 314-362-4357 or dial 911.

Table of Contents

Personnel & Hours

For general inquiries, please use the Contact page. Other issues (or shipping) can be addressed to the Director of the Neurotech Hub:

Matt Gaidica, PhD

4370 Duncan Ave

Neurotech Hub // Room 2115

Our goal is to be open 9 AM – 4 PM every weekday. Availability of equipment will be reflected in the Schedule.

Machining

When using the “dirty” tools, please pay extra attention to your hair, clothes, and shoes (closed-toe only). Although thick gloves are useful for handling material, they are prone to snagging on anything sharp and rotating. In general:

- Read the manual and understand the machine’s safety instructions

- Wear appropriate personal protective equipment (PPE) like safety glasses or goggles

- Maintain a clean and organized workspace

- Secure the workpiece using clamps or a vise

- Use the appropriate blade or bit for the material being cut (ask if you don’t know)

- Keep hands a safe distance away; consider using push sticks or blocks for saws

- Avoid reaching across a running machine

- Never leave a machine unattended

Please use the appropriate workshop areas for machining. Metal debris ejected onto (or into) electronics is a major hazard.

Preferred Vendors for Raw Materials

- Industrial: McMaster-Carr, Instrument Machine Shop can next day deliver

- Plastic: Cope Plastics (Alton, IL)

- Wood: Home Depot

- Metal: Central Waste Material Co. (St. Louis, MO)

Sorry, we do not store your raw materials. If you want to leave materials in the Hub, you should consider them a donation for community use.

Laser Cutter

We have a Boss LS-2440 105-watt CO2 laser (View the Spec Sheet or LS Series Manual). Fumes are escaped and filtered by a Filtrabox Expand X-2. The laser connects to a PC and is configured for cutting using Light Burn Software. The cutting capability is shown below (all materials above metal can also be engraved):

| Material | Cutting Capability |

|---|---|

| Soft Wood | 0.50″ – 1/2″ – 12.7mm |

| Hard Wood | 0.375″ – 3/8″ – 9.5mm |

| MDF | 0.25″ – 1/4″ – 6.35mm |

| Acrylic | 0.375″ – 3/8″ – 9.5mm |

| Most Textiles | YES |

| Leather | 0.187″ – 3/16 – 4.76mm |

| Metals | Engrave Only |

Please watch the brief safety video below to acquaint yourself with the general theory and applications of CO2 lasers.

Next, visit the LightBurn Tutorial Series and watch (at least) the following videos:

- Tutorial #1: First time user – device setup

- Tutorial #2: User interface and feature walk through

- Tutorial #3: Cut settings

- LightBurn Basics: Importing, selection, grouping, movement

You may also find similar information in the LightBurn Online Documentation.

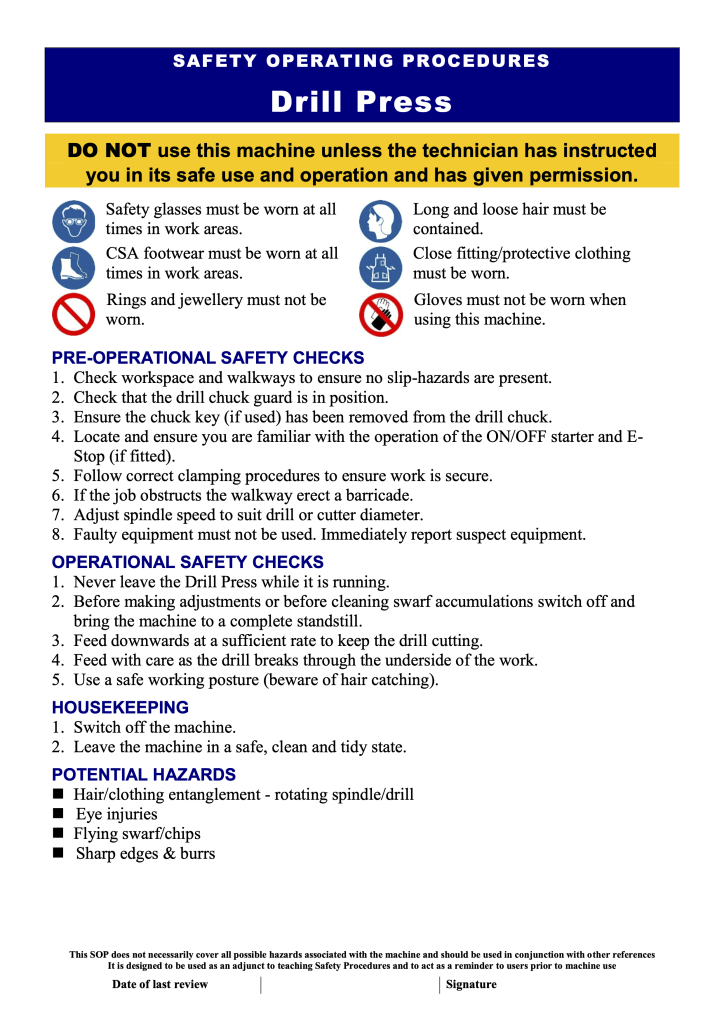

Drill Press

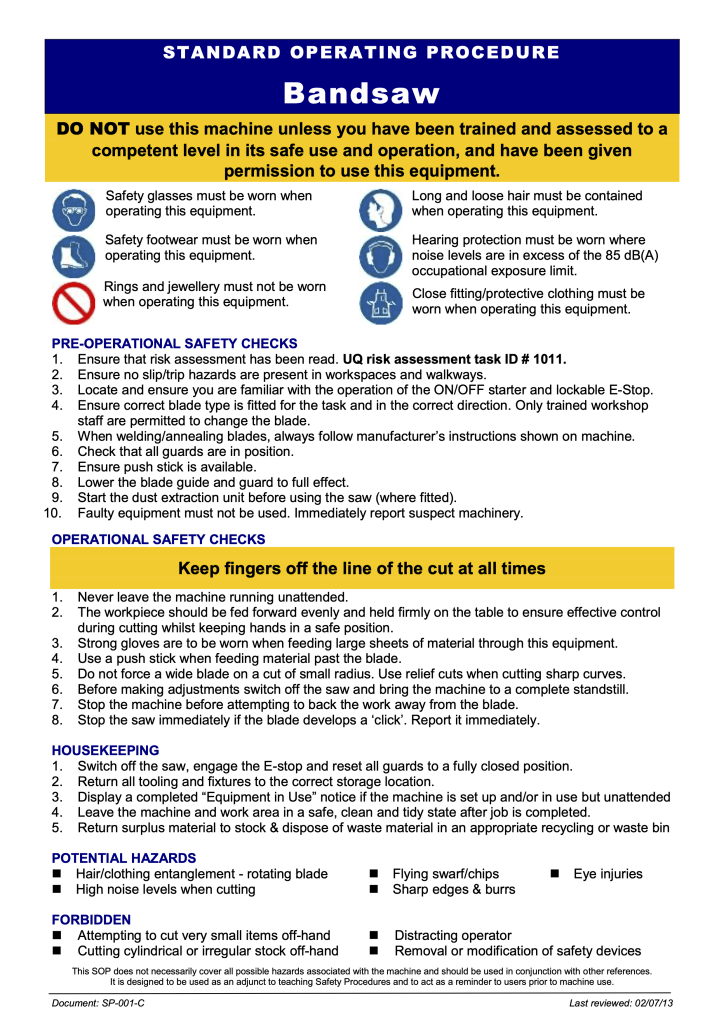

Bandsaw

We have a Jet HVBS712D bandsaw that can be arranged in a horizontal or vertical position with the option to feed hydraulic fluid onto metal parts for “cold cutting” (view the HVBS712D Manual).

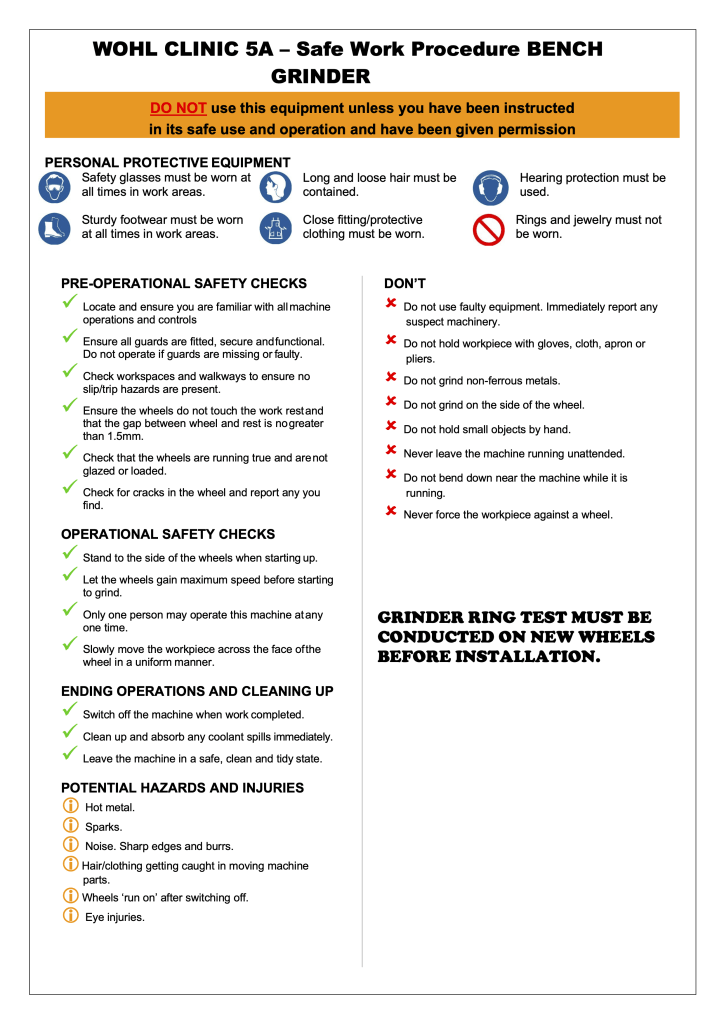

Bench Grinder

Soldering & Circuits

We have a fully outfitted electronics lab including soldering irons (standard and hot-air machines, reflow oven), oscilloscopes, multimeters, power supplies, a vector impedance analyzer, and more. Once we understand your project needs we can properly align (or refer) you to tools and training.

The high-precision tools are reserved for people who really need them and are familiar with basic soldering and rework techniques. Some of the equipment you’ll find in the Hub is listed below:

- JBC High-precision Hot Air

- JBC 2-tool Nano Rework

- JBC PCB Pre-heater

- 3.5x-90x Stereo Microscope with 18 MP Camera

Soldering

Soldering is simply the art of bonding metals, often using flux to aid in heat dispersion and conduction. Adafruit has an excellent guide on Making a good solder joint.

Surface-mount components benefit from automatic alignment via surface tension when using hot air machines or reflow ovens, which you can watch an example of below:

Students and faculty may also access the Spartan Light Metal Products Makerspace for soldering and testing equipment.

Special Projects

While we work to bring manufacturing capabilities under our roof, we will work with any number of vendors for PCB and PCBA projects. Some companies we have worked with include:

- uFab (St. Louis, USA)

- JLC PCB (China)

- PCBWay (China)

- Sierra Circuits (USA)

Our preferred vendors for parts are either Mouser Electronics or Digi-Key.

We should also point out the Institute of Material Science & Engineering facilities, including a thermal evaporator (e.g., parylene coatings).

3D Printing

We have several machines in-house for filament and resin 3D printing (What’s the difference?).

This means we can do everything from bio-compatible, miniature implants, to large, custom enclosures made out of hardened plastic (e.g., ABS).

Long-duration prints. We understand some projects take a long time to print. However, our general rule is that prints should occur within the scheduled time window for your piece of equipment and not be left to run overnight. Get in Touch for prints that exceed 8 hours.

3D Design & Slicing

Thinking in terms of 3D—extrudes, paths, cuts—is the major hurdle for most individuals. While we typically train on and use Autodesk Fusion 360, 3D design software is really a matter of preference and licensing.

- Autodesk Fusion 360 (Free for educational use, subscription-based for commercial use)

- Tinkercad (Free)

- Blender (Free)

- SketchUp (Free version available, SketchUp Pro has educational discounts)

- SolidWorks (Educational discounts available, paid commercial software)

- FreeCAD — also consider the more intuitive RealThunder fork on GitHub

For those ready to jump in, we recommend the YouTube series, Learn Autodesk Fusion 360 in 30 Days for Complete Beginners!

Slicing refers to how a design is “sliced” into layers for the 3D printer to interpret. You might be wondering, why isn’t that built into the design software? It’s kind of like how a computer will have separate printer settings or configuration areas (the slicer) that any program can interface with (e.g., pressing ⌘p in your browser). And while design software is usually printer agnostic, slicers are sometimes built with specific printers in mind. The good news is, most slicers are open-source:

Other Equipment

An unsuspecting tool we have is a Cricut Maker 3 that can cut a variety of materials without the potential of thermal damage that the CO2 laser might produce. You can use Cricut Design Space for free on your computer or phone and push your designs over Bluetooth to the Cricut; just don’t get sold on their ecosystem of paid-for fonts and upgrades. Some of the things we’ve cut include:

- Small foam or rubber gaskets

- Vinyl for labels or t-shirts

- Cloth for rodent harnesses

We also have a Husqvarna VIKING Jade 20 sewing machine; no material is left behind. This machine can be used to interact a fabric, rubber, and other synthetics.

The Washington University campus also has an enormous amount of tools that we do not wish to replicate. Take a look at some of these Additional On-Campus Resources to view equipment and schedule training.

Terms & Agreements

Access & Use

Users must be trained on each piece of equipment before use. “Wear and tear” of equipment is understood but we expect users to replace tools if they are broken due to misuse or failure to follow the appropriate training guidelines. No tools may be borrowed unless given explicit permission.

Safety is of utmost importance. Each process will have different safety requirements, but in general, users should be making use of eye protection, ventilation, and pay attention to long hair, jewelry, or unsuitable clothing. We provide a limited number of safety glasses, gloves, and other safety-related items to our users. The Neurotech Hub has 24/7 private video monitoring for everyone’s safety.

We require workstations and projects to be cleaned at the end of each day. We may or may not be able to store and manage your stock or inventory. Membership or user fees will generally cover consumables.

Acknowledgment

If the Neurotech Hub was integral to your publication, we request that you acknowledge us in your manuscripts or grants:

“This research made use of the Neurotech Hub at Washington University in St. Louis.”

Please share your submissions with the director. Co-PI, co-authorship, letters of collaboration, intellectual property, or commercialization can be discussed case by case.