Services

We provide a variety of technical services on-demand or as part of a larger, long-term project.

Broadly

- Make tools or find them

- Ideate/prototype form factor

- Identify technical constraints

- Take concept to solution

- Seek/advocate for new tools

- Get your preliminary data faster

Specifically

- 3D design and prototyped parts

- 2D parts: acrylic, wood, vinyl, etc.

- Electronics design, assembly, & testing

- Flexible/exotic material manufacturing

- Embedded coding (Arduino, MATLAB, C)

- Training: you can do it!

If you think you will use the Hub often, Membership has a variety of advantages that eliminate hourly billing.

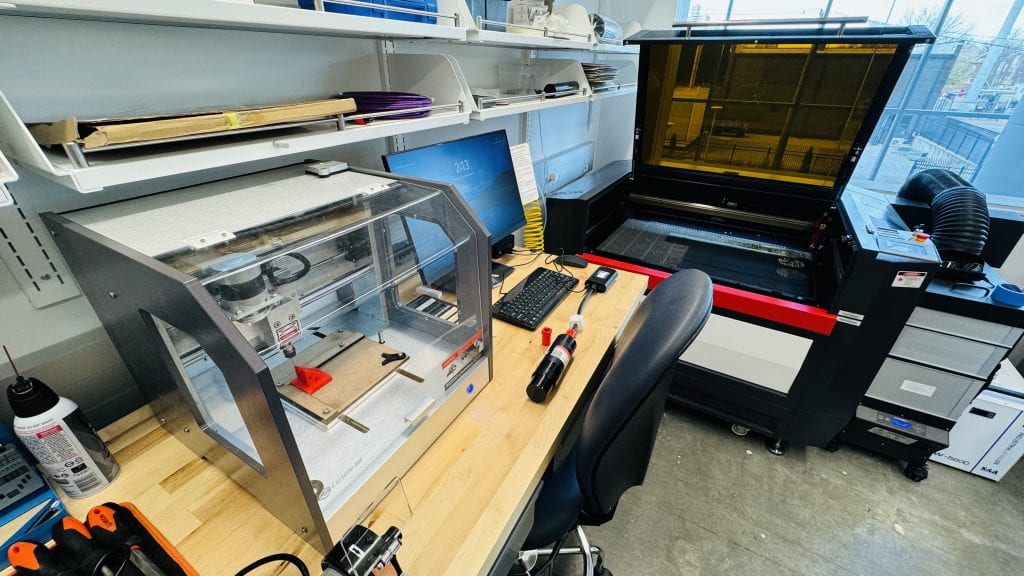

Capabilities

Our shop has over 700 sq. ft. of working space and tooling with a wide range of capabilities.

Electronics

- Vevor T926A Reflow Oven

- Saleae Logic Pro 8 (signal analyzer)

- Otti Arc Pro by Qoitech (power meter)

- Soldering: general purpose & rework

- FLIR ONE Edge Pro Thermal Imager

- Power supplies, oscilloscopes, multimeters, vector network analyzer

We have state-of-the-art electronics capabilities. We strongly believe that smaller electronic platforms that utilize flexible or exotic substrates will allow our community to address new and exciting problems across organisms.

For larger projects, we may recommend utilizing third-party assembly services and can help make those connections.

Material manufacturing

- Keyence 6W UV Laser (2 µm spot size)

- FormLabs Form 3B Printer (Resin)

- ETEC D4K Printer (Resin)

- Bambu X1 Carbon Printers (Filament)

- Boss LS-2440 105W Laser Cutter

- Carbide Nomad 3 Desktop Mill

- Jet HVBS-712D Cooled Bandsaw

- Cricut Maker 3 (vinyl, fabric, foam)

- Drill press, rotary tool, grinder, belt sander, vices, etc.

We cover a wide range of material capabilities from ≥25µm bio-compatible 3D printing to laser cutting large acrylic stock (up to 0.25″) or ablating exotic materials with our precision UV laser.

For large footprints projects, we will likely refer you to the experts in the Instrument Machine Shop.

3D Printer Materials

| Printer Type | Material | Colors |

|---|---|---|

| Resin | FormLabs White | White |

| Resin | FormLabs Black | Black |

| Resin | FormLabs Biocompatible | Clear, Amber |

| Resin | FormLabs Rigid 4000 | White |

| Filament | PLA | Black, Gray, White, Blue, Red |

| Filament | ABS | Green |

| Filament | PETG | Army Green |

| Filament | TPU (Flex) | Black |

| Filament | Varishore (Flex) | Black |

| Filament | PLA-CF | Black |

| Filament | PLA Support (Washable) | White |

Some of our capabilities require specialized, extensive training. This is to increase the longevity of our assets and provide a safe working environment. It is best to Get in Touch if you have questions.

What we don’t

We take pride in finding a way, but there are certain things we will generally say “no” to. They include:

- n >> 50 parts (in-house)

- Handle large part ordering/inventory

- Debug existing software or perform IT work

- Unearth old or undocumented electronics

- Cut/sand wood (due to dust)

Schedule

You must Request Training before scheduling equipment; all members are required to use the schedule. After selecting your piece of equipment below, you will choose a calendar based on your membership level. Excessive no-shows may compromise membership status—we thank you for being responsible stewards of our time and yours!

Not working? Try visiting https://neurotechhub.as.me/